-40%

2HP Air Compressor Duty Electric Motor 56 Frame 3450 RPM 120/240V 5/8" Shaft US

$ 63.9

- Description

- Size Guide

Description

2HP Air Compressor Duty Electric Motor 56 Frame 3450 RPM 120/240V 5/8" Shaft USFeatures:

2 HP SPL 3450 RPM, 56 Frame, 120/240V, 15/7.5Amp 5/8" Shaft, Single Phase NEMA Air Compressor Electric Motor

Open dripproof Single phase Full Load amps: 15/7.5Amp, 120/240V 2 HP SPL 3450 RPM 5/8 Shaft in. NEMA

Reduced starting amperage design to ensure the reduced voltage starting at rated load.

Equipped with UL approved Manual thermal overload, capacitors and high quality ball bearings to ensure the lifetime.

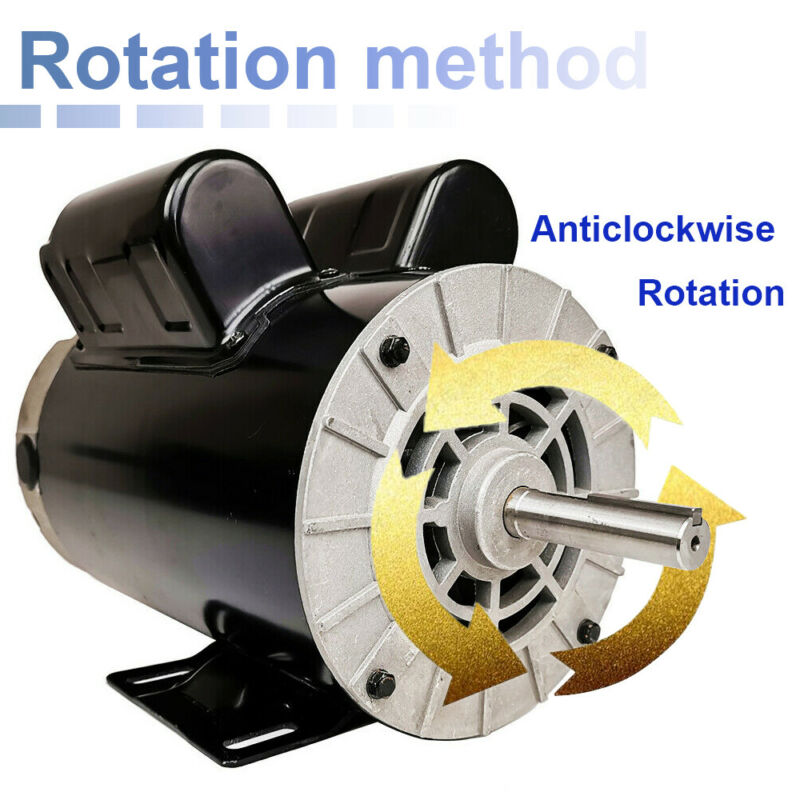

Open drip-proof is better used in environment that are relatively clean and dry environments. Special design for Air Compressor duty. CCW only.

Special design for Air Compressor duty.

Motor is Non-Reversible CCW (Counter Clockwise) ONLY.

Default settings are default low-voltage current. If the need to use high-voltage current, please replace the use of high voltage wiring.

Technical Info:

Type:COMPRESSOR DUTY MOTOR

Power Source:AC

AC Phase:Single Phase

AC Frequency Rating:60 Hz

Base RPM:3450 RPM

Enclosure Type:ODP (Open Drip-Proof)

Full Load Amps:15

Fram Type:56

Shaft lenght:2 1/16"

capacitor:star and run

Service Factor:1.0

Rated RPM:3450

Amperage:(7.5 FLA @ 240V) (15 FLA AT 120V)

Shaft Diameter:5/8" Keyed shaft

PH:1

AMB:40℃/104℉

Duty:CONT.

CODE:F

INF.CL:F

Warranty: 2 Year

PROFESSIONAL INSTALLATION IS REQUIRED.

PACKAGE LIST

1 x 2 HP SPL Compressor Duty Electric Motor

1 x Manual

Please Feel free to contact us with any questions you have relating to our products.

Kindly Tips:

Below is a quick check list for you to reference when sizing up the right motor for your application.

1. Amperage

This is your electric motors TRUE power rating. Please make sure your FL amp (FULL LOAD) rating on the motor you're replacing is within 10% of the FL Amp rating of the motor you intend to buy.

2. Frame Size

The frame not only constitutes the bolt pattern, it also depicts the overall size and torque. The larger the frame, the stronger the motor. It's extremely important that you replace it with the same frame size. Improperly sized motors will inevitably result in motor failures.

3. Phase and Voltage

If your machine requires a 230V electric motor on single phase power. You would want to incorporate a 1-phase 230V AC electric motor for your application. 230V electric motors cannot handle voltages less than 208V. They will run too hot and you will experience motor failure.

4. RPM

Matching up the RPM is quite important. The wrong speed can damage your pump. The RPM does not have to match exactly, but you do need to be the neighborhood.

Example: 3510rpm, 3550rpm, 3450rpm are all the same. They are all fall under the umbrella of whats known as 3600RPM motors.

5. Shaft Diameter

With a tape measure. Measure the outside diameter on your electric motors shaft. By matching up the proper shaft diameter, you will be able to reuse the original motor pulley that came on your machine.

On Jan-18-21 at 19:41:11 PST, seller added the following information: